News

Zhejiang Double Arrow Rubber Co., Ltd.

At the intersection of industrial innovation and intelligent automation, Double Arrow is quietly reshaping the landscape of traditional bulk material handling. With its intelligent conveyor belt system, the company is setting a new benchmark in how materials are moved—making systems smarter, more aware, and less dependent on manual oversight.

Backed by decades of expertise, Double Arrow understands the urgent demands facing industries like mining, ports, power generation, metallurgy, chemicals, coal, transportation, and building materials. These sectors require conveyor systems that are not only more intelligent and reliable, but also energy-efficient and easier to manage. The result? A next-generation solution that merges advanced technology with sustainability: the Double Arrow Intelligent Conveyor Belt.

Four Key Features Driving the Intelligence Revolution

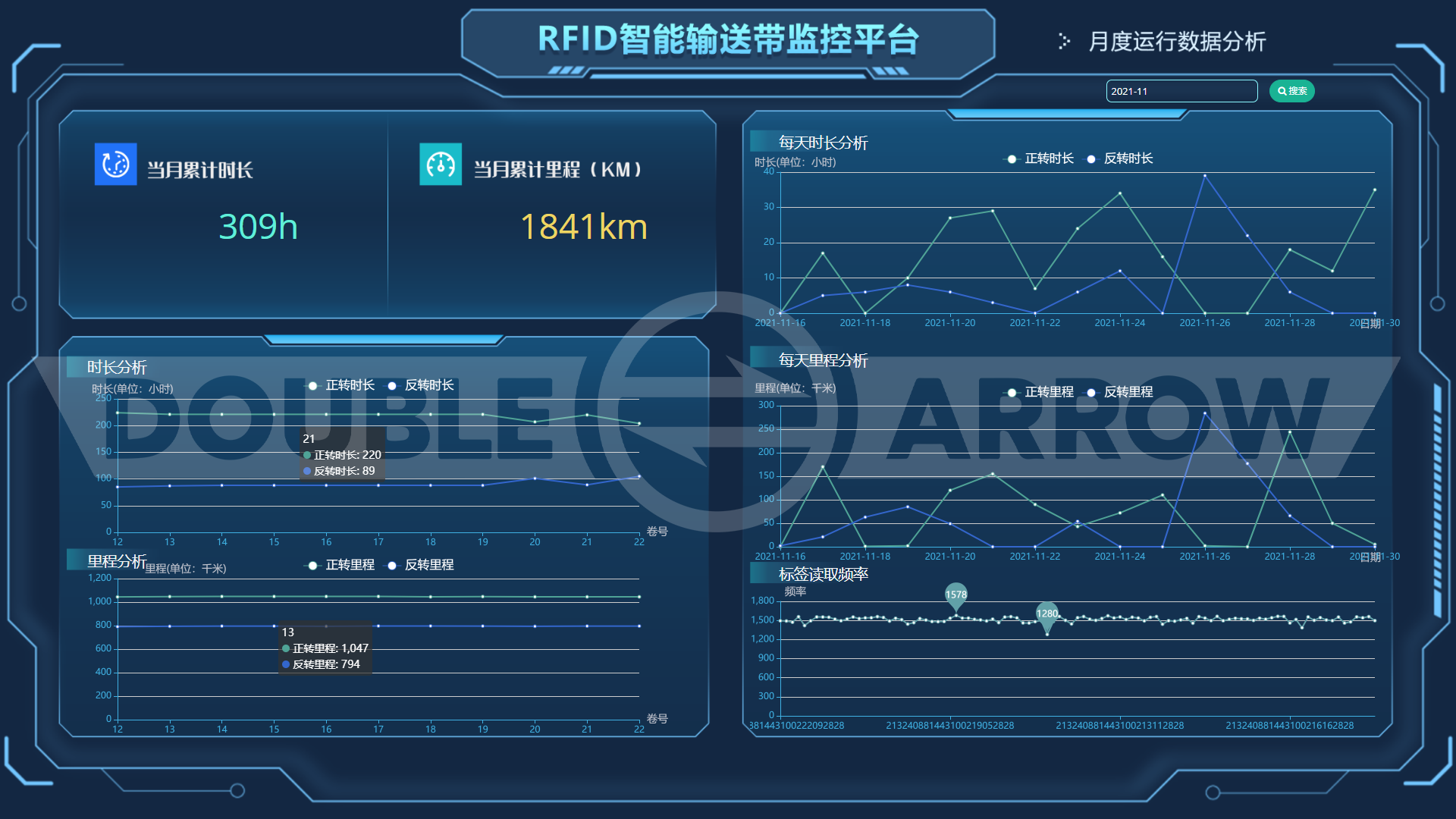

RFID-Enabled Lifecycle Management: Total Traceability from Start to Finish

Every intelligent conveyor belt is embedded with a passive RFID chip—essentially a unique digital ID that enables full lifecycle tracking and traceability. From production through installation to end-of-life service, users can instantly access detailed performance data: belt speed, mileage, hours of operation, tonnage carried, and more.

The system doesn’t just display data—it interprets it. When operational thresholds are reached, automated alerts are triggered, enabling proactive maintenance and minimizing the risk of unexpected downtime. The RFID system also supports pinpoint stopping for targeted inspections or repairs, enhancing efficiency and safety across the board.

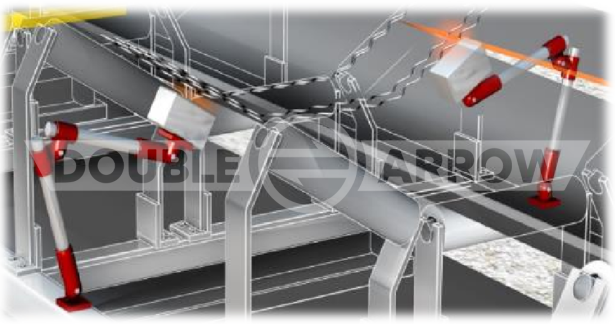

Embedded Anti-Tear Coils: Proactive Protection with Zero Compromise

Longitudinal tears, surface abrasions, and joint separations are some of the most costly and disruptive failures in conveyor operations. To counter these risks, Double Arrow employs embedded smart coils that continuously monitor belt integrity in real time.

This early-warning system identifies signs of potential tearing at the earliest possible stage, often before visible damage occurs. The benefits are extensive:

· Minimizes unplanned downtime and production losses

· Reduces repair costs by avoiding emergency fixes

· Extends belt lifespan, optimizing capital investment

· Automates inspection and diagnosis, cutting labor input and improving safety

As digital mining and 5G-enabled infrastructure expand, this technology offers an increasingly intelligent and seamless approach to safety management.

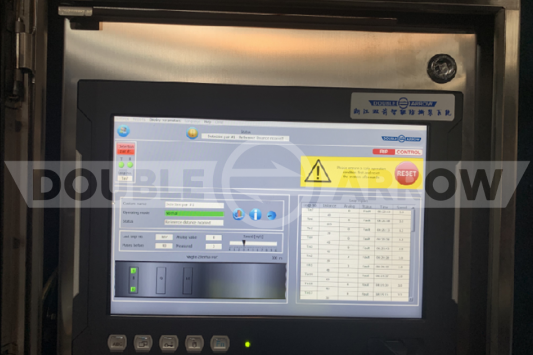

Precision Joint Monitoring: Millimeter-Level Insight, Maximum Confidence

Splice joints—the weakest point in any conveyor belt—are now safeguarded by a dedicated smart joint monitoring system. This feature provides continuous, high-resolution data (up to 0.5mm precision) on joint wear and elongation.

It’s not just monitoring; it’s insight with actionable outcomes. Users can define custom alert thresholds and emergency protocols. If deterioration is detected or failure is imminent, the system responds immediately—either alerting operators or triggering a full system shutdown.

In the rare event that prior alerts are missed, the system's built-in intelligent decision engine acts as the final line of defense, halting operations if structural failure is imminent. It's more than just a safety net—it’s intelligent risk management in action.

Steel Cord Damage Detection: Real-Time Health Monitoring of Your Belt’s Core

For steel cord belts, core integrity is critical. Double Arrow's real-time steel cord monitoring system works like an X-ray for your conveyor, scanning continuously to assess internal health with high accuracy.

Its capabilities go beyond simple detection:

· Tracks and compares damage progression across operational cycles

· Offers predictive insights into wear patterns and degradation rates

· Supports custom damage grading based on user-defined risk tolerance

· Enables data-driven, condition-based maintenance decisions

With this system, repairs are no longer based on guesswork or conservative estimates. Instead, maintenance becomes a precision task—strategic, timely, and cost-effective.

Leading the Smart Manufacturing Revolution

As industries around the world pursue smarter, safer, and greener operations, Double Arrow’s intelligent conveyor solutions are positioned at the forefront of this transformation. Whether you're operating a high-throughput mine or managing a complex logistics hub, these advanced systems deliver the data transparency, predictive capability, and operational security needed to compete in today’s fast-evolving industrial landscape.

浙公网安备33048302000315号

浙公网安备33048302000315号

Copyright ? 2017 DoubleArrow.Net All right reserved.

网站建设:博采网络